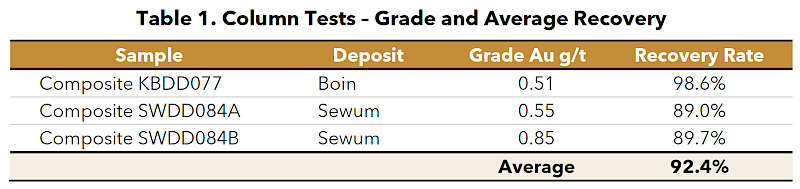

Ghana – Newcore Gold Ltd. announced positive results from three additional column tests completed as part of the ongoing metallurgical program at the Company’s 100%-owned Enchi Gold Project (“Enchi” or the “Project”) in Ghana. An average gold recovery of 92.4% was achieved from column testwork completed on two composite samples from the Sewum Gold Deposit (“Sewum”) and one composite sample from the Boin Gold Deposit (“Boin”).

Three Column Tests Completed, Average Gold Recovery of 92.4% Achieved. A total of three column tests (two from Sewum and one from Boin) returned an average gold recovery of 92.4%, with a recovery range of 89.0% to 98.6%. Testwork Further Advances the Understanding of Processing Options for Enchi.

Testing completed on representative samples from diamond drill core.

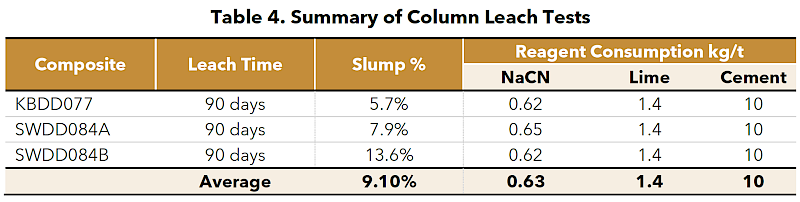

Coarser samples used better represent modelled crush size for heap leach processing. Larger sized samples used in the columns with each sample weighing 30 kg. Low Reagent Consumption.

Coarser grind size compared to prior testing contributed to lower consumption for cyanide as well as lower required amounts of lime and cement per kilogram.

All samples showed modest cyanide consumption with an average of 0.63 kilograms per tonne (“kg/t”), with a 1.4 kg/t lime (hydrated) addition to maintain a pH above 10.5. Additional Metallurgical Testwork Planned Optimization work to be completed on additional column tests.

Further planned metallurgical work to consist of a bench-scale test to be completed in the field on the Project. Testing of sulphide mineralization to be completed in 2023. Greg Smith, VP Exploration of Newcore stated, “This additional set of column tests completed on diamond drill core material from the Enchi Gold Project returned consistent results with high recoveries for all three composite samples, highlighting the amenability of Enchi to heap leach gold recovery.

These samples are representative of the oxide and transitional material from the two largest deposits, Sewum and Boin, which together currently comprise approximately 87% of the Enchi Inferred Mineral Resource Estimate. Of note these samples were much coarser than material used for previous testwork and were more in line with the parameters of the Preliminary Economic Assessment completed in 2021. The coarser material resulted in a series of positive benefits including continued excellent recoveries, lower required reagent levels for lime and cement and lower cyanide consumption and slumping.”

A total of three composite samples, two from Sewum and one from Boin, were submitted for column testwork to the Intertek Lab located in Tarkwa, Ghana, approximately four hours by paved road from the Enchi Gold Project. Material for the metallurgical samples consisted of half diamond drill core from holes drilled specifically to collect material for metallurgical sampling. The samples were selected to represent the two largest deposits on the Project, Sewum and Boin, and consisted of blended oxide and transitional material. For each deposit, individual samples included a range of gold grades and weathering intensities.

Composite KBDD077 was prepared using 15 samples from diamond drill hole KBDD077 drilled at Boin with a total weight of 41.6 kgs. Composite SWDD084A was prepared using 18 samples from diamond drill hole SWDD084 drilled at Sewum with a total weight of 42.5 kgs. SWDD084B was prepared using 16 samples from a second mineralized interval in diamond drill hole SWDD084 with a total weight of 38.6 kgs.

Recovery for the three samples averaged 92.4 %, with a range of 89.0% to 98.6%.

Composite samples were homogenized by mixing all material from the individual samples and crushed to 70% passing 10 mm. Each composite sample was then split to provide four sub-sample weighting 1,000 grams each, then used for screening and grading analysis, head sample analysis, and five-day coarse bottle roll leach test.

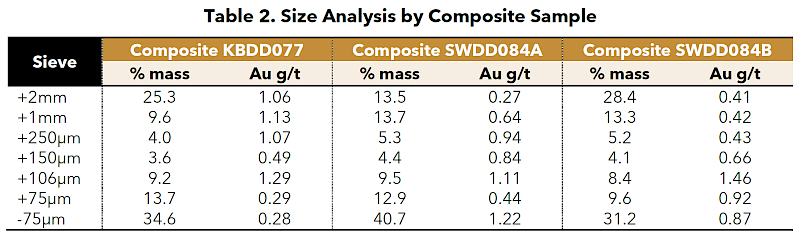

A size analysis was done on each of the three composite samples. The samples were tested at seven screen sizes and included analyses for percent mass. The samples were assayed for gold which showed that gold was present in all size fractions analysed. The distribution shows relatively consistent gold grades for all size fractions within a range of 0.41 grams per tonne gold (“g/t Au”) to 1.46 g/t Au, with three outliers grading between 0.27 and 0.29 g/t Au. Results include 49% to 63% passing 150 microns indicating that agglomeration is warranted, and each of the three composite samples were agglomerated at 10 kg/t of Portland cement.

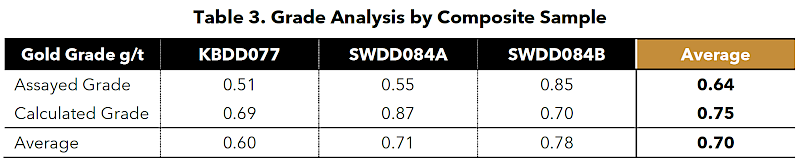

Using the results of the sizing and grading analysis, a head grade was calculated for each of the composite samples. The results were then compared to the head grade assays which were completed on the 50-gram subsamples. The results compared well for the three composites with each having an average grade representative of the average grade of the deposits.

Simulated heap leach testing was conducted on the composite samples using one-kilogram sub-samples which underwent leaching for five days. Batch dissolution tests (five days, intermittent rolling-bottle) was completed under excess leach conditions (50% solids, leach time: five days, pH 10.5, NaCN (sodium cyanide) addition 1 gram/litre). The final residue was dried, weighed, and assayed for gold. After each of 1, 2, 3, 4 and 5 days of leaching, solution assays were taken and analyzed, and reagent consumption was calculated (cyanide and lime).

For composite KBDD077, 80.8% of the gold was recovered on the first day, with recoveries increasing constantly as the days passed to about 94.1% on the fifth day. For composite SWDD084A, 58.0% of the gold was recovered on the first day, increasing to 75% on the fifth day. For composite SWDD084B, the dissolution curve was constant over the five days, with 77% of the gold recovered on the first day and 76.3% on the fifth day.

In all cases leaching continued after the first five days with ultimate recoveries expected to continue to increase with additional time. Metallurgical Testing – Column Tests

Three 30 kgs closed-cycle column leach tests were conducted on the samples as received. The test charge was loaded into 150 mm in diameter by 1.5-metre-tall PVC columns. 30 kgs of the individual samples were agglomerated in a rolling drum using Portland cement at a 10 kg/t addition rate and then allowed to air dry for three days. After the samples had been air dried, they were loaded into the columns with the columns tilted at an angle to avoid stacking before being set upright. The column was then allowed to sit for a day before the initial level was taken to determine the slump.

The leaching parameters used in this column leach test included the addition of approximately 1.4 kg/t of lime which was blended into each feed solution and a cyanide concentration of 1,000 ppm. The initial feed solution was prepared by adding lime to tap water to obtain a solution pH above 10.5 followed by the addition of one gram of sodium cyanide per litre of solution with a solution application rate of 10L/h/m2 for all samples. The column testwork was conducted under a closed cycle for 90 days. All solution samples were assayed for gold and pH and free sodium cyanide was analyzed and recorded. Leach residue was thoroughly washed, dried, screened and analyzed for gold by fire assay.

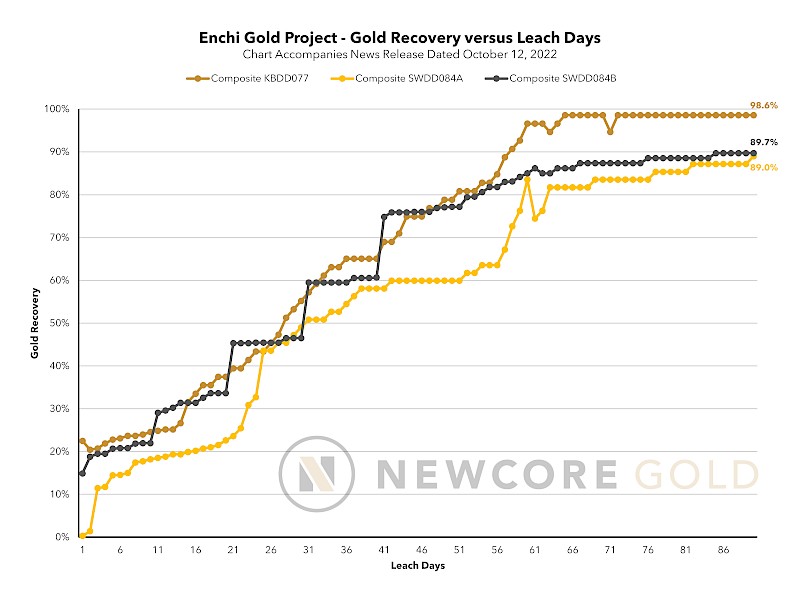

The column tests are aimed at simulating the response to leaching of the sample with the emphasis on establishing the gold dissolution characteristics (rate and extent), reagent consumption, and the degree of slumping within the ore bed. All samples showed amenability to heap leaching, with recoveries averaging 92.4% after 90 days.

The samples showed low cyanide consumption averaging 0.63 kg/t with a 1.4 kg/t lime (hydrated) addition to maintain a pH above 10.5. The slumps were within acceptable industry standards with an overall average of 9.1%. The sample responded well to a percolation rate of 10L/m2/hr with some minimal flooding. The optimum percolation rate will be studied and optimized.

The column leach test program has shown that the gold in the ore samples tested is readily leachable and amenable to heap leaching. The recoveries achieved are considered high and are interpreted to indicate the strong amenability to heap leaching. The particle size distribution and size by size analysis performed on both the head and residue after leach showed that the maximum gold recovery occurred in the finer fractions as compared to the coarser size fractions.

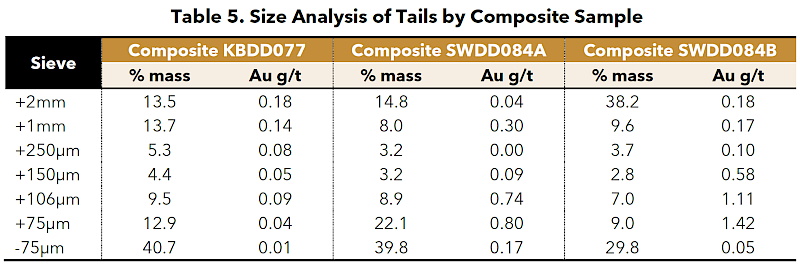

Screening and Grading Analysis of Tails Samples

A size analysis was done on all the tails from the composite sample column tests. The samples were tested at seven screen sizes including analyses for percent mass and assayed for gold. The distribution shows consistently low grades of gold for all size fractions within a range of 0.00 g/t Au to 0.80 g/t Au with two outliers of 1.11 and 1.42 g/t Au.

Enchi Gold Project Mineral Resource Estimate

The Enchi Gold Project hosts a pit constrained Inferred Mineral Resource of 70.4 million tonnes grading 0.62 g/t Au containing 1.41 million ounces gold (see Newcore news release dated June 8, 2021). Mineral resource estimation practices are in accordance with CIM Estimation of Mineral Resource and Mineral Reserve Best Practice Guidelines (November 29, 2019) and follow CIM Definition Standards for Mineral Resources and Mineral Reserves (May 10, 2014), that are incorporated by reference into National Instrument 43-101 (“NI 43-101”). The Mineral Resource Estimate was prepared by independent qualified person Todd McCracken, P. Geo. of BBA E&C Inc. The technical report, titled “Preliminary Economic Assessment for the Enchi Gold Project, Enchi, Ghana” has an effective date of June 8, 2021, and is available under the Company’s.

A 5,000 metre discovery and resource expansion drill program, following up on the success achieved to date from drilling at Enchi, commenced in Q3 2022. Diamond drilling will focus on continuing to define the higher-grade sulphide mineralization at depth with a goal of delineating the potential for high-grade underground resources at Enchi. Reverse Circulation (“RC”) drilling will target near-surface oxide and shallow sulphide mineralization with a goal of outlining additional resource growth along strike and depth at all deposit areas. RC drilling will also be planned to follow-up on discoveries made as part of the recently completed 90,000 metre drill program. Additional exploration work is also on-going, including metallurgical testwork and trenching of high-priority surface anomalies.

A 90,000 metre discovery and resource expansion drill program (commenced in August 2020) was completed at Enchi in Q2 2022. The program included both RC and diamond drilling and included the first deeper drilling on the Project. Newcore’s multi-pronged exploration approach delivered on the goals set out at the start of drilling: (i) successfully outlined potential resource growth along strike at all four existing deposits (Sewum, Boin, Nyam, Kwakyekrom); (ii) encountered strong results at previously drilled zones that are outside of the resource area (Kojina Hill and Eradi); (iii) drilling intersected high-grade at depth which has outlined the potential for underground resources; and (iv) identified new discoveries from successful first pass drilling on early stage kilometre-scale gold-in-soil anomalous targets (Sewum South, Tokosea). The total planned drill program consisted of 575 holes representing 92,583 metres.

Newcore is committed to best practice standards for all exploration, sampling and drilling activities. Drilling was completed by an independent drilling firm using industry standard RC and Diamond Drill equipment. Analytical quality assurance and quality control procedures include the systematic insertion of blanks, standards and duplicates into the sample strings. Samples are placed in sealed bags and shipped directly to Intertek Labs located in Tarkwa, Ghana for 50 gram gold fire assay.

(Source: Press Releases – www.newcoregold.com/news/newcore-gold-announces-92.4-gold-recoveries-in-column-testwork-for-the-sewum-and-boin-deposits-at-the-enchi-gold-project-ghana/)

Please send your press releases to press@miningnewspaper.com or juan.lamadrid@miningnewspaper.com